Failed Blister Repairs

A Case History and Solutions

by David Pascoe, Marine Surveyor

John Williams is the proud owner of a ten year old 35 sloop. Prior to his purchase, he spent nearly a year searching around the country to find this particular yacht because it ideally suited his needs. When the survey was conducted, there was only one significant problem with it: it had a scattering of small blisters on the bottom, which I usually refer to as "pimple rash" to differentiate this condition from considerably larger blisters. The blisters in this case were no larger that 1/4" in diameter and had a density of about 2-3 blisters per square foot if averaged over the entire bottom area.

Case

John lived in California and eventually moved boat from these cool waters to Florida. Suddenly the 90o waters of Florida's waterways caused the number of blisters the number of blisters to blossom from perhaps a few hundred to several thousand. Not liking what he saw, he decided to have them repaired. Obtaining three estimates on the cost, he finally settled on the Ace Boatyard, in part because they used the West Epoxy system and Williams had heard that this material was highly successful at solving the blistering problem. The cost was $7,000 and he was given a 5 year guarantee. He was also told that the repair would eliminate his blistering problem, although the yard manager did tell him that it was possible that "a few" blisters could possibly reappear.

The repair method included stripping off all the paint and old gelcoat with a specially designed machine by an outside contractor. This was followed by "fairing" and recoating the bottom according to the instructions provided by the manufacturers of the West System. In addition, it also included "hot coating" the bottom, a method described to me as applying the antifouling bottom paint to the bottom while the last coat of West System epoxy was still wet.

The job was completed, Mr. Williams paid his bill and went on his way, pleased that his blistering problem had now been repaired and solved. At least until a year later when the yacht was hauled and he discovered that about 50% of the blisters had reappeared. Returning to the yard that did the work, his complaint was greeted with a response somewhat different than what he was told prior to giving the yard his $7,000. Now the blister job was no longer a cure for the problem but simply a repair of the existing blisters. Moreover, all of the blisters that reappeared were new ones they said, unrelated to the ones just recently repaired. That meant that, although Ace Boatyard did indeed warrant that the blisters they repaired would stay fixed, the new blisters were not a reappearance of the old blisters, and therefore not covered by their 5 year warranty.

Mr. Williams estimated that about 1/3rd of all the blisters returned within one year, and he wasn't buying Ace's revision of their warranty. He was told that the repair would end his blistering problem, but it did not. The yard showed no sign of wanting to compromise the matter so he sued.

The yard's defense counsel hired a surveyor to look at the boat, and after doing so pronounced that the entire hull had severe delamination problems, determined by "sounding with a phenolic hammer." Nothing else was done to verify the "delamination." The yard then hung their defense on the premise of preexisting manufacturing defects as the reason why the repair wasn't successful and blisters recurred.

Multiple causes of blister reappearance

Called as experts for Mr. Williams, we examined the yacht after the newly applied bottom coating had again been removed, the bottom being stripped down to the skin out mat and in some cases right down to roving. Our sounding of the hull produced not the slightest indication of even possible delamination of the hull.

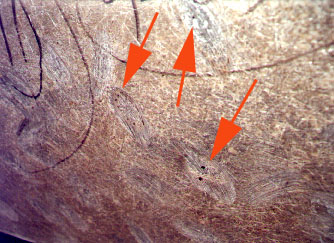

After removal of the newly applied barrier coatings, this is what Mr. Williams hull looked like. Most, if not all, of the original blister voids remained. At right, the new resin can be seen to have been applied directly over the old blisters.

Multiple causes for the reappearance of the blisters became immediately apparent. These are as follows:

- As show in nearby photos most, if not all, of the old blister cavities

were still present. As far as we could determine, no effort was made to

grind away the cavities or void areas and fill them.

- Scattered and random areas of the original skin out mat, as part of the

original lay up, had significant areas of unsaturated fibers and minute

voids, i.e. air bubbles in the original lay up.

- Some areas which had been faired with an unknown filler, but looks like

two-part epoxy, were very soft and pliable, giving the appearance that it

had not been mixed in proper ratios and did not cure properly. Since some of

this material was hard, and some soft, we do not consider it likely that the

material softened of its own accord.

- Judging by the coloration, it was apparent that two applications of a clear resin (although a few areas showed three) and one layer of a fairing material had been applied, the former by roller without being brushed out. In most areas where the barrier coating remained, it was usually found to be very thin, notably thinner than a typical gel coating. We estimate this at about 10 mils. A thick gel coat would be 30 mils, a thin one 20 mils.

Failure to correct imperfections

The failure to correct these imperfections provided the basis for the reformation of both the old and new blisters. Bearing in mind that the movement of the yacht from cool waters to the 90o waters of the canals of Ft. Lauderdale resulted in a very rapid development of blisters, the yard had every reason to believe that the blistering of this hull was likely to continue at a rapid rate since Mr. Williams had explained all of this to them.

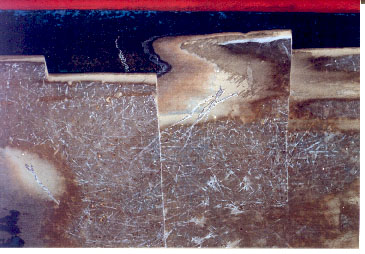

Fairing material that either turned soft or was not properly mixed and catalyzed.

Although these blisters were ground away, the void spots or air bubbles within the skin out mat that initiated the blisters are clearly evident in this photo. If the voids are not removed, then the potential for reformation remains.

Assuming that the moisture meter used to determine that the hull had indeed dried out prior to recoating was accurate, this case, and many others like it, seem to belie the common notion that epoxy resins are significantly less permeable than polyester. Otherwise, it's difficult to explain why large numbers of blisters reappeared so rapidly. Either the hull was never really dry, or somehow it once again absorbed water.

Another shortcoming in the repair process was found, that the new coating had been applied with a paint roller and never leveled out. This left a surface texture that was quite rough, resulting in a surface mill thickness that was very irregular. Whether this had an affect on the reblistering hasn't been empirically determined, but if barrier coat thickness has anything to do with the rate of permeability, then it's certainly reasonable to assume that it did.

Scrape marks were made with the end of a ball point pen to indicate how soft it is , a perfect environment for blister formation. This is the point where the bottom was faired into the old gelcoat at the boot stripe. Note blister voids at lower center.

It also appears that a two-part epoxy filler was used in the fairing process that amounted to no more than 25% of the bottom area. This included spot filling depressions of what might have been larger blisters, as well as fairing around through hull fittings, fairing the waterline into the removed bottom gelcoat, as well as just general fairing.

The fairing process was poorly accomplished, resulting in a "lumpy" appearance to the finished job. Most significantly, as we have found in a large number of other failed blister jobs, the fairing material, whatever it is, was found to be soft and pliable. Whether this resulted from improper mixing and incomplete curing, or if the material softened from water exposure or resultant chemical reactions, was not precisely determined. However, it would certainly be difficult to sand a filler that was not completely cured, and the fact of the lumpy appearance of the bottom suggests this possibility.

On the other hand, our finding of so many other fillers that turn soft also suggests the likelihood of problems of;

(1) incompatibility of materials being combined, or

(2) that these materials are severely affected by contact with sea water.

All we can say for certain is that it is a two-part mix and that the material in many areas, although not all, was very soft.

Paint blisters

A final flaw was discovered in that many of the blisters (we don't know what percentage because 90% of the bottom paint was removed) had occurred not under the new epoxy coating, but between the new coating and the new application of bottom paint. In other words, they were bottom paint blisters. And paint blisters are often misinterpreted as barrier coat blisters.

Since there was only one type and coating of bottom paint on the hull, this can't be attributed to incompatibility of bottom paints which, as we know, is usually the cause of paint blisters. So why would a brand new antifouling coat blister like this? Did it have something to do with the "hotcoating?" We would have to conclude that it must have, for there would seem to be no other explanation.

Examination under magnification suggested a possible answer, since each blister that we dissected and examined revealed a pit, or indentation extending into the new epoxy barrier coat. The presence of the pit would suggest that a chemical reaction did indeed take place to cause the erosion that created the small pits and blisters in the paint.

Obviously, this begs the question of whether applying an antifouling coat to a wet epoxy barrier coat is a good idea. It may save the boat yard the task of sanding the bottom before painting, but it certainly didn't make the paint adhere any better.

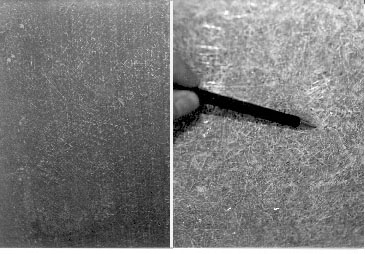

Comparison view of fully saturated skin out mat at left, poorly saturated mat at right also showing numerous void spots or air bubbles. Notice that no blisters appear in the fully saturated laminate.

Myth about blisters

As we have stated in other articles, blister repair failures like these are becoming commonplace. One reason is due to the fact that there is such a great deal of misinformation floating around out there about the nature of the problem.

Over the last decade, I have looked at thousands of blistered boat bottoms and I know one thing for certain. I have never seen blisters occurring in a laminate that did not have voids or unsaturated fibers. It can't happen because there must first be a void space of sufficient size to collect water in sufficient volume to initiate the blistering process. I am convinced that, lacking the voids, blisters cannot form.

The significance of this is twofold. First, for builders it means that if one ensures that there is a thorough wet out of the skin out mat, resulting in fully saturated fibers and minimal voids between gel coat and mat, and between mat and first structural layers, blisters will not form unless you are using third rate materials.

This photo, not this essay's subject vessel, shows a boat bottom with at least two dozen grind spots in little more than one square foot area.

Despite all the grinding, hundreds of voids and areas of unsaturated fibers remain. When the condition of the skin out mat is this bad, it cannot be successfully repaired. It must be removed completely. Unfortunately for the owner, the yard simply filled the holes and recoated it, with a high probability that the repair will fail.

Secondly, the same point applies to repairs. The uncorrected problems associated with Mr. William's failed blister repair are common to nearly all others. If the repairer eliminates the voids that help initiate the problem in the first place, he eliminates most of the potential for recurrence. Most repairers are knowledgeable enough to know that they have to remove the existing blister voids, and do so. Yet from touring boat yards and watching their process, it is clear that most are not dealing with the problem of poorly saturated fibers from the original construction. Recoating over a poorly saturated skin out mat occurs again and again.

This presents the repairer with something of a problem because to eliminate the unsaturated fibers in the skin out would mean that a lot of it has to be stripped away and replaced. The problem here is that this would significantly increase the cost to the customer that is likely to meet with resistance. There is a solution to this that will be explained further on.

Causes of blisters and factors involved

While there is a great deal of myth about blisters, we have learned so far that:

- The vast majority of blisters occur between the skin out and the gel

coat.

- A slightly smaller percentage occur within the skin out mat, or between

the skin out and the first structural laminate.

- Blisters occurring within the structural laminate, particularly woven fibers, are extremely rare.

There are a number of factors involved in why this is so:

- Chopped strand mat is difficult to fully saturate and a very high

percentage of all boats have unsaturated mat. That some do not blister

suggests the use of far less permeable gelcoats and resins, or that some

resins are more chemically stable than others.

- The formation of blisters is associated with the softening of the

barrier coat due to the presence of precipitated solvents from the resin

(styrene) in a void space, and the build up of slight gas pressure

sufficient to form the blister. But the pressure build up has been found to

be very weak, so that the deformation of the blister may be less due to

pressure than the effect of expansion of the gel coat caused by solvent

softening. The mechanism is much the same as pouring acetone on cured paint,

causing it to wrinkle.

- Blisters do not form in the structural laminates if only because these

heavy fibers are too strong to permit deformation of the laminate. On the

other hand, gel coats and barrier coats are not fiber reinforced and are

thus far more prone to surface deformation. For a blister to develop from a

tiny air bubble between layers of roving, for example, would require a very

high pressure indeed to result in deformation. On the other hand, random

directional mat fibers are quite weak.

- These points lead to the seemingly inescapable conclusion that poor saturation of skin out mat has to play a pivotal role in blister formation. If anyone has any doubts about this, try taking a tour through the boat yards and see if you can find blisters occurring within thoroughly saturated laminates. I can tell you in advance that you won't.

It is reasonable to conclude from this that, while epoxy and vinylesther resins are still sufficiently permeable to fail to prevent blistering, the elimination of most of the unsaturated fibers in the skin out mat will preclude most of their reformation when combined with higher quality resins.

Bottom line to blister repairs

It is foolish for a boat yard to give a 100% guarantee on blister repairs, for it is not possible to eliminate all voids close to the surface. Yet it is possible to remove 90% of the voids through careful preparation. Bear in mind that if it requires completely stripping the skin out mat, then there's no reason not to do so. It doesn't have to be put back on since the only reason for it's presence is to prevent telegraphing of roving pattern to the gelcoat, and that's not a consideration on the bottom of a hull. If the structural layers prove to be well-saturated, as they usually are, then the problem is going to be 90% solved.

Here is a particularly good shot of unsaturated fibers in a skin out mat. These really stand out because the layup resin in this hull is tinted dark blue.

In most cases, the poorly saturated fibers do not stand out this well. In this case, as in so many others, the repairer simply applied a new barrier coat on top of this mess and the blisters reappeared with six months.

The bottom line to blister repairs is that there are far too many people in

the business who don't know what they're doing. They apparently are not aware

that for the repair to be successful, they must eliminate the defects that

caused the blisters in the first place. Yet it is not possible to determine

all of the factors that cause blistering, especially the cause of water

getting into the laminate.

The buzzword is "osmosis," as if permeability of coatings is the only means of

water saturation. The reality is that we can identify a half-dozen ways that

water can get into a laminate that have nothing to do with exterior coatings.

So even if there were a totally effective, non-permeable coating, it would not

solve the problem, for you can't prevent the absorption of water from the

interior of the hull, or around through hull fittings and so on.

But the one method that offers the greatest possibility of a cure is to

eliminate the voids within the outer laminations where blisters commonly form.

And if that means stripping the chopped strand mat from the hull, then that is

what has to be done. Otherwise, it's just money down the drain.

Related Articles:

The Wonderful World of Hull Blistering

Avoiding the Blister Blues

First posted on Sept 2, 1997 at David Pascoe's site: www.yachtsurvey.com.

Page design changed for this site.

Power Boat Books

Mid Size Power Boats

Mid Size Power Boats A Guide for Discriminating Buyers

Focuses exclusively cruiser class generally 30-55 feet

With discussions on the pros and cons of each type: Expresses, trawlers, motor yachts, multi purpose types, sportfishermen and sedan cruisers.

Selecting and Evaluating New and Used Boats

Dedicated for offshore outboard boats

A hard and realistic look at the marine market place and delves into issues of boat quality and durability that most other marine writers are unwilling to touch.

2nd Edition

The Art of Pre-Purchase Survey The very first of its kind, this book provides the essentials that every novice needs to know, as well as a wealth of esoteric details.

Pleasure crafts investigations to court testimony The first and only book of its kind on the subject of investigating pleasure craft casualties and other issues.