Exhaust Risers

Whether you're a stinkpotter or rag boater,

this arcane and disinteresting subject is of major importance to your wallet.

by David H. Pascoe, Marine surveyor

Page 1 - Page 2

All marine inboard engines have exhaust risers. The exhaust riser has two functions:

(1) to keep water from backing up into the engine through the exhaust

piping and,

(2) it serves as the device that introduces cooling water into the exhaust

exit piping system.

If the riser fails to accomplish either of those jobs successfully, the end result is the arrival of Uncle Big Bill on the scene.

Contents - Page One

IntroductionCorrosion Failures

Cast iron

Thickness of Water Jacket

with 4 photos

Continue to Page Two

Aluminum Risers

Leaking Gaskets

Sail Boats

Diesel Engines

Leaks

Epilogue

with 4 photos

Introdction

As someone who has evaluated hundreds of engine damage insurance claims, I can tell you that exhaust riser failures -- either in the design of the thing, or by corrosion failures -- is the single largest cause of engine damage and premature engine failure.

Riser problems come in two flavors: Corrosion failures and design failures. If you wish to keep Uncle Big Bill at bay, you need to understand the following points.

Corrosion Failures

All common gasoline engines use cast iron risers, as do most small auxiliary sail boat engines. Cast iron, of course, corrodes, and is a lousy material to make risers with. Problem is, there isn't anything better. At least not that you're willing to pay for. If you have extra $$$, have them custom machined from titanium and you will solve the problem. That would set you back about $5,000 apiece, so in the meantime we're stuck with cast iron.

Actually, for the low cost, cast iron works pretty well. But, like the tires on your car, they do not last indefinitely. Depending on how well they are designed -- for design has an awful lot to do with it -- some last longer than others. Mercruiser, for example, has a wonderful reputation for risers that sometimes don't last a year. On average, in saltwater use, good risers last about 4-5 years. At 4 years, you should start worrying about them.

Mercruiser 4.2 V6 riser. Arrow shows where corrosion hole occurred. It doesn't take much corrosion to block these small water passages. Note that the passages top and bottom only have a tiny hole where it met the larger passages on the manifold. Hard to figure this one???

Merc 350 riser. Notice the difference, especially the width of the gasket surfaces between the openings. This one had been cleaned of scale and put back in service. That didn't stop it from leaking and ruining the engine, which it did.

Cast iron

Cast iron works well because it tolerates extremes of temperature, expansion and contraction better than other options like stainless steel. Since cooling water is injected into the exhaust heated part, there is usually a zone of very high temperature difference -- a transition zone from superheated to quickly cooled. If you were to heat up a cast iron skillet red hot and then pour cold water in it, you know that that would probably crack the pan apart. Same thing with risers. Ergo, how they are designed has a lot to do with it. The heat transition zones result in more rapid rates of corrosion.

Cast iron corrodes in a unique way, depending on type, it corrodes with a sort of sheeting action, or a blistering action, leaving layers of heavy scale on the corroded surfaces. It is not unusual for that scale to become 1/4" thick. When the scale gets that thick, it ends up blocking the water flow. The other problem with this is that this scale stays wet, retains water, a situation which advances the corrosion process. Unlike aluminum or Corten steel, the corrosion does not serve to protect the metal, quite the opposite. Therefore, as cast iron corrodes, the rate of corrosion becomes progressive. Meaning that the rate of corrosion becomes faster. Get the picture here? Right. By the time you see corrosion on the exterior, it's time to start worrying.

Thickness of the "jacket"

It is the thickness of the "jacket," the wall between the exhaust chamber and the cooling water, that determines how long it will last. The thinner it is, the sooner it will fail, but you have no way of know what the thickness is. So you're sort of stuck waiting for the apocalypse.

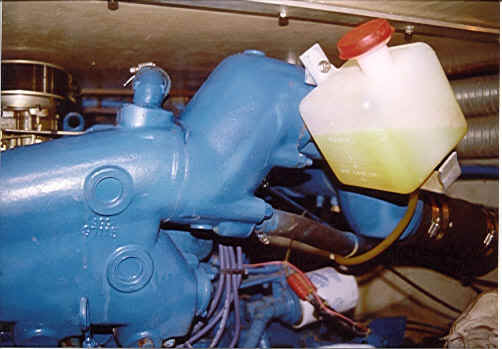

This Crusader 454 riser system is 12 years old. That's because the riser is closed system cooled. Naturally, it costs more money. The water induction elbow is behind the coolant bottle and is a lesser expensive throwaway. Notice the oil filter adapter where you can easily reach it.

Crusader riser, salt water cooled. This design uses a steel insert ring with the water passage all around it. It too, is narrow and over time became completely blocked with scale.

As with engine blocks, risers have water passages inside that also corrode. Some riser designs, like those of Mercruiser, have passages that are so narrow that the rust scale can quickly block those passages. This causes two problems. (1) it reduces cooling water flow through the whole engine and causes engine overheating, or (2) it can cause the exhaust system to starve for cooling water, overheat, and possibly setting the boat on fire. Neither make for happy days.

Even worse though, if corrosion makes a hole between the water jacket and the exhaust chamber, then the cooling water can go down into the exhaust manifold, flood it, into the valves and then the cylinders. This is a very unfortunate state of affairs because it can wreck the engine. You don't want this to happen because it probably is not covered by insurance, meaning you pay. Of course, you cannot see that hole because it's on the inside. One day you go to start your engine and nothing happens. The starter clicks and clunks. Water has seized the engine up. On that day, there will be much wailing and gnashing of teeth.

The moral of the story here is that you need to do one of two things. Pay Little Bill to stave off Big Bill. Or wait and pay Big Bill.

(1) If you have corrosion appearing anywhere on the riser exterior, it is time to pull them and have them inspected internally. Replace them if Mr. Goodwrench recommends that. Trying to salvage wasted risers is not worth the risk.

(2) At the end of 4 years, automatically pull the riser(s) and have them inspected, even if there is no external corrosion. Just because you don't see it on the outside, doesn't mean that the riser may not be about to fail.

No, it does not matter how many hours there are on the hour meter. The hour meter measures itself, not the rate of corrosion and is totally irrelevant to anything. Throw them overboard; hit them with a hammer; rig them to a bomb, send it to your mother-in-law; change your oil by them. Whatever. But do not judge the condition of your engines by them. They don't mean anything short of a meaningless number.

Posted January

24, 1999 (First posted October 23, 1998 at www.yachtsurvey.com).

Power Boat Books

Mid Size Power Boats

Mid Size Power Boats A Guide for Discriminating Buyers

Focuses exclusively cruiser class generally 30-55 feet

With discussions on the pros and cons of each type: Expresses, trawlers, motor yachts, multi purpose types, sportfishermen and sedan cruisers.

Selecting and Evaluating New and Used Boats

Dedicated for offshore outboard boats

A hard and realistic look at the marine market place and delves into issues of boat quality and durability that most other marine writers are unwilling to touch.

2nd Edition

The Art of Pre-Purchase Survey The very first of its kind, this book provides the essentials that every novice needs to know, as well as a wealth of esoteric details.

Pleasure crafts investigations to court testimony The first and only book of its kind on the subject of investigating pleasure craft casualties and other issues.